nima.mohamadin

عضو جدید

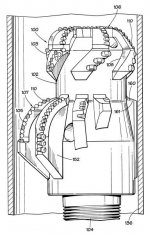

5th Generation Bi-Center Technology

- Optimized pilot cutting structure that will drill out and drill ahead in a single run

- Patented geometric balancing

- Reduced imbalance to conventional PDC bit levels

- Centralizes pilot providing it with full gauge contact for superior hole quality

- Improves bit stabilization with over 180 degrees of gauge contact

- Increases wear resistance with more cutters opening the pilot hole

- Reduces rock cutting loads on the reamer

Steerable Bi-Center bits are also available for applications using point-the-bit rotary steerable systems.